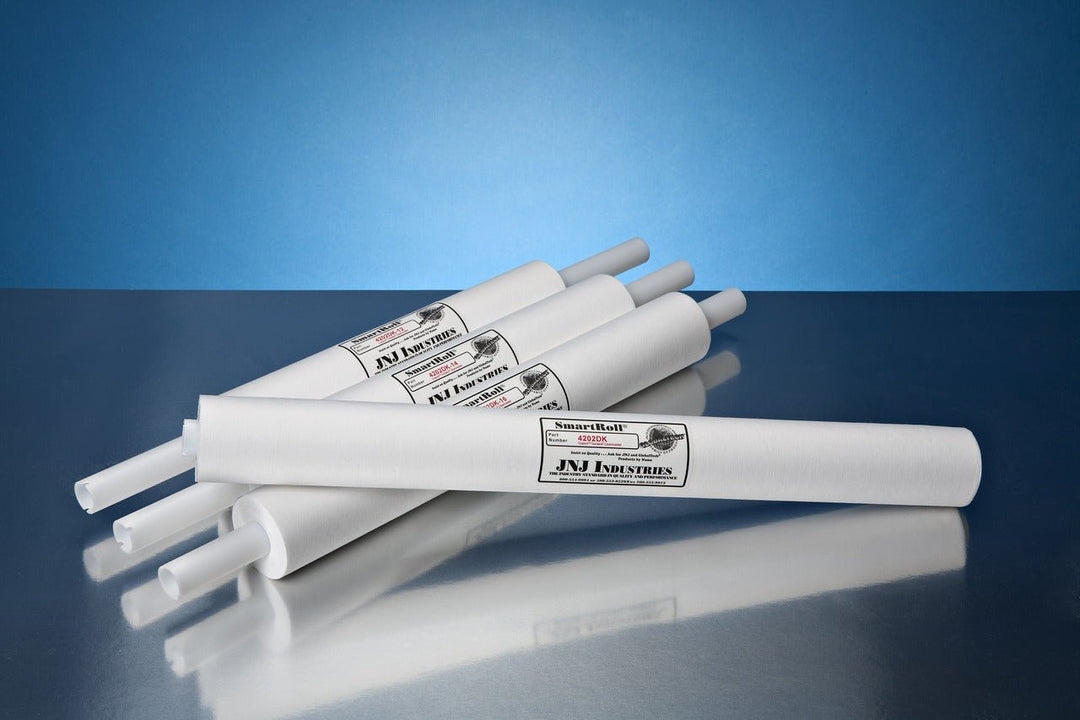

JNJ Industries 4202DK-16 SmartRoll Understencil Wiping Roll DEK 20.87 in x 36 ft - .75 in, paper width / 16 in /15 rolls per case

JNJ Industries 4202DK-16 SmartRoll Understencil Wiping Roll DEK 20.87 in x 36 ft - .75 in, paper width / 16 in /15 rolls per case

Most DEK printers use stencil rolls that are based on the same core tube, which is a plastic tube with a .75" inside diameter (19.5mm), that is 20.87" Long (530mm). The typical roll outside diameter is 2.25", and it has 36 linear feet of paper per roll. The full width roll has paper that is 20.37" wide (515mm), but some boards or printers are set up to accommodate a roll with narrower width paper. It is important to make sure that when using a roll with paper that is not the full width that if a solvent bar system is being used, that the paper width is equal to or larger than the width of where the solvent is dispensed from the solvent bar.

Product Description

4000 Series is a hydroentangled blend of 54% cellulose / 46% polyester cleanroom grade wiping roll for cleaning under stencils between prints. This material effectively removes residual adhesives, solder pastes and fluxes, with or without solvents. Using our high quality wiping roll will help prevent many common production defects like bridging, smearing, solder balls, and other problems associated with circuit board printing. Due to its excellent

airflow characteristics, this material will not compromise vacuum power, optimizing aperture cleaning performance. Made from Sontara® fabric, the one material that does it all. 4000 Series UnderStencil Wiping Rolls are the standard in wiping technology!

Hydroentanglement: also known as spunlacing, entangles the fibers to give strength to the web. It uses fine, high-pressure jets of water to strike a web to intermingle the fibers, resulting in the bonded fabric being a nonwoven. Nonwovens made by this method have high fabric integrity.

Static Dissipative ESD Safe Film: SmartRolls are shrink wrapped in a protective static dissipative ESD safe film with superior static control capabilities. Our static dissipative ESD safe film has the lowest surface resistivity, that remains at a constant level over extended periods. This transparent film is amine-free and has inherent antistatic properties which provide permanent product stability. Its contact clarity allows easy identification of the packaged contents. Made of top grade polylefin resins, is polycarbonate compatible, completely recyclable and contains no harmful substances. Our shrink film is a light packaging concept that is environmentally safe and limits post-consumer waste.

SmartRolls® understencil wiping products exceed the demanding requirements of the equipment manufacturer and by offering the widest range of OEM compatible rolls in the global market today.

Features:

Absorbent: highly absorbent and fast wicking ~ wicks consistently across the material to ensure a more productive clean.

Strong: advanced structure of exceptional strength, even went wet ~ tear and shred resistance raises MTBF (mean time between failures) and reduces operator intervention, increasing efficiency.

Non-abrasive: soft texture, won't scratch surfaces, wet or dry.

Low Particle: extremely low in soluble extractables and metallic ions - no binders, starches or thermal bonding techniques. The absence of binder or surface modifiers minimize contamination.

ESD Packaged: each roll is shrink wrapped in protective film. Chemical Tolerance: won't break down, resistant to all current Surface Mount solvents.