Humidity, Temperature & Static: How Environment Impacts ESD Risk and Cleanroom Performance

Humidity, Temperature & Static: How Environment Impacts ESD Risk and Cleanroom Performance

In cleanrooms and electronics manufacturing, small environmental changes can make a big difference. Humidity and temperature directly influence electrostatic discharge (ESD) risk, contamination levels, and operator comfort. Keeping these in balance helps protect sensitive components, improve yields, and maintain compliance.

ESD ControlQualityAudit-Ready

Why Humidity & Temperature Matter

- Dry air (<30% RH) increases static generation and slows dissipation.

- High humidity (>70% RH) can promote condensation and corrosion on sensitive surfaces.

- Target 45–55% RH and stable temperatures (about 68–75°F) for most ESD-sensitive processes.

Monitor What Matters

Measuring and documenting humidity, temperature, and surface resistance is core to any ESD control program. Routine checks help catch drift before it impacts yield.

ACL Staticide ACL 800 Digital Megohmmeter

Verify resistance of mats, flooring, and wrist straps at the point of use—and log results alongside ambient conditions to strengthen your ESD records.

Simple, Visual Humidity Checks

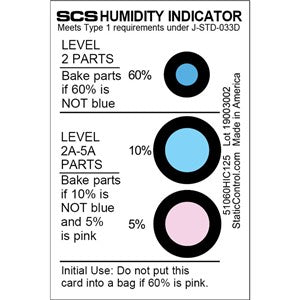

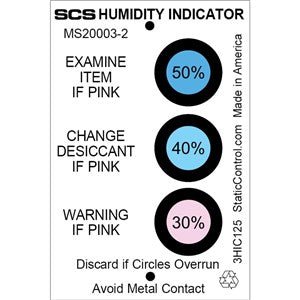

Humidity can swing with seasons, HVAC settings, and process heat. A fast, low-cost way to confirm conditions (especially inside packages and storage) is to use humidity indicator cards.

Humidity Indicator Cards – Collection

Each dot changes color at a specific RH level, giving technicians an instant visual readout for sealed packaging, storage cabinets, or incoming inspection.

Humidity Indicator Card – 3-Spot (125/Can)

A compact variation for sealed packaging or storage containers—simple, cost-effective, and perfect for verifying humidity in ESD-sensitive environments.

Create a Balanced Environment

- Integrate monitoring: Check RH and temperature during regular ESD audits.

- Correlate data: Review environment logs with ESD test results to spot trends.

- Prevent drift: Add humidification/dehumidification where seasonal swings are large.

- Train teams: Include environment awareness in ESD training and daily walkdowns.

Maintain your program with MTE’s full line of Static Control Products. Need help matching tools to your requirements? Contact us.

Explore more

- 3M

- 3M Tapes

- 9 Mil Gloves

- Absorbent Mats

- Absorbent Pads

- Absorbent Pillows

- ACL Staticide

- Adhesive Sealants

- Adhesives

- Aerospace Application

- Akro-Mils

- American Made Swabs

- Anaerobic Adhesives

- Ansell

- Anti-Fatigue Mats

- Anti-Static

- Anti-Static Bags

- Aprons

- Arm Guards

- Audio

- Aven

- Aven Microscopes

- Aven Mighty Vue

- Aven ProVue Deluxe Magnifying Lamp

- Aven ProVue Magnifying Lamps

- Aven ProVue MAX and ProVue MAX UV

- Aven ProVue SuperSlim Magnifying Lamp

- Aven Stereo Zoom

- Aven Tools

- Aven Wide View Magnifier

- Beard Covers

- Benchtop Ionizers

- Bent Nose Pliers

- Berkshire

- Berkshire Mats

- Berkshire Swabs

- Best Practices for Cleanrooms

- best-selling cleanroom consumables

- BFN802

- Bins

- Biodegradable Cleanroom Wipes

- Blu-Tek Tweezers

- Botron

- Boufannts

- Bouffant Caps

- Brady

- brady labe

- Brady Label

- Brady Label Printers

- Brady Labels

- Brady Printers

- Brady SPC

- Bubble Tray Liners

- Carbofib Tweezers

- Charge Plate Monitors

- Chef Hats

- Chemical Repackaging

- Chemicals and Cleaners

- Chemtronics

- Chip Quik

- Circuit Board Repair

- Circuit Board Troubleshooting Guide

- CircuitWorks

- Circus

- Class 5

- Cleaning Products

- Cleaning Solder

- Cleaning Supplies

- Cleaning Wipes

- Cleanroom

- Cleanroom Apparel

- Cleanroom Beard Covers

- Cleanroom Best Practices

- Cleanroom Classifications

- Cleanroom Compliance

- cleanroom consumables best sellers

- cleanroom consumables shelf life

- Cleanroom Coveralls

- Cleanroom Documentation

- Cleanroom Dry Wipes

- Cleanroom Electronic Repair Tools

- Cleanroom Essentials

- cleanroom essentials gloves wipes mats swabs

- Cleanroom Face Masks

- Cleanroom Frocks

- Cleanroom Gloves

- Cleanroom Gloves and Apparel

- Cleanroom Gowns

- Cleanroom Labeling

- Cleanroom Maintenance

- Cleanroom Mops

- Cleanroom Notebooks

- Cleanroom Packaging

- cleanroom packaging solutions

- Cleanroom Paper

- Cleanroom Pens

- Cleanroom PPE

- Cleanroom Presaturated Wipes

- Cleanroom Products

- Cleanroom Protocol

- Cleanroom Regulations

- Cleanroom Safety

- Cleanroom Standards

- Cleanroom Sticky Mats

- Cleanroom Supplies

- Cleanroom Sustainability Solutions

- Cleanroom Swabs

- Cleanroom Trash Bags & Liners

- Cleanroom Waste Management

- Cleanroom Wipe Supplier USA

- Cleanroom Wipes

- cleanrooms swabs

- Cloud Based VMI

- Co-Packing

- Coil Cords

- colors

- Columbia Cleanroom

- Conductive

- Conductive Coatings

- Conformal Coating

- Conformal Coating Dots

- Conformal Coating Remover

- Conformal Coating Tapes

- Conformal Coating Thinners

- Contamination Control

- contamination control consumables storage

- contamination control essentials

- contamination control supplies

- Contec

- Contec Polynit

- Corstat

- Cost-Effective Cleanroom Products

- Cotton Swabs

- cotton swabs for non-critical cleaning

- Coveralls

- Coveralls with Hoods

- Custom Coil Cords

- Custom Thermoforming

- Cutters

- Cyanoacrylate Adhesives

- Degreasers

- Desco Industries

- Desco Statshield bags

- Desoldering Braids

- Diagnosing Overheating Components

- Digital Megohmmeter

- Disinfectants

- Dispensing

- Dispensing Nozzles

- Dou Yee

- Dry Wipes

- Dual Port Soldering Station

- Dymax

- E-Z Pik

- Eclipse

- Eco-Conscious ESD protection

- Edge Series Cutters

- Electrical Tapes

- Electronic Component Failures

- Electronics Assembly

- EMI/RFI

- Environmentally Safe

- ESCA Tech

- ESCA Tech D-Lead Paint Test Kit

- ESCA Tech PT-KIT-24-1.0 D-Lead Paint Test

- ESD

- ESD Bags

- ESD Bin Boxes

- ESD Boots

- ESD Cleaning Wipes

- ESD Cleanroom Swabs

- ESD Damage

- ESD Equipment

- ESD Explained

- ESD Floor Mats

- ESD Floors

- ESD Footwear

- ESD Garments

- ESD Gloves

- ESD Jackets

- ESD Material Handling

- ESD Mats

- ESD Monitors

- ESD nitrile gloves for electronics

- ESD Packaging

- ESD packaging for cleanrooms

- ESD Palm Coated Gloves

- ESD Personal Grounding

- ESD Products

- ESD Protection

- ESD Protection in Cleanrooms

- ESD Risk

- ESD Safe Anti-Fatigue Mats

- ESD Safe Packaging

- ESD Safe Pens

- ESD Safe Products

- ESD Safe Shipping

- ESD Safety

- ESD Scissors

- ESD Shielding Bags

- ESD Shipping Boxes

- ESD Shoe Covers

- ESD Shoes

- ESD Socks

- ESD Storage

- ESD swabs for PCB assembly

- ESD Table Mats

- ESD Test Equipment

- ESD Testers

- ESD tools for cleanrooms

- ESD Training

- ESD Transport

- ESD Wrist Straps

- Ethyl Adhesives

- Exam Gloves

- Excelta

- Excelta Discounted

- Excelta Pliers

- Excelta Scissors

- Excelta Tweezers

- EZ Grip Black Tweezers

- Face Masks

- Fan Ionizer

- fast wetting

- Field Meters

- Finger Cots

- Flame Retardant

- Flat Nose Pliers

- floor marking

- floor markings

- Flux

- flux cored

- Flux Remover

- Foam Packaging Material

- FOD Awareness

- Foil Tapes

- Food Industry Apparel

- Food Industry Gloves

- Freeze Spray

- Freeze Spray For Electronics Repair

- Frocks

- Global Glove

- Gloves

- Gown Room Procedures

- Gowning

- Green cleanroom supplies

- Grounding

- Hairnets

- Hakko

- Hakko FX971

- Hakko FX972

- Hand Held Magnifiers

- Hand Tools

- HandPro 1700 Nitrile Gloves

- Healthcare

- Heat Guns

- Heel Grounder

- Heel Grounders

- HexcelPack

- HexcelWrap

- Hi-Tech Conversions

- High Quality Hand Tools

- High Tech Conversion

- High-tech Conversions

- High-Tech Conversions Sticky Mats

- Hourglass Airsoft900

- Hourglass AQUA1900

- Hourglass Fortis 500

- Hourglass Freestyle 1100 Nitrile Exam Gloves

- Hourglass Handpro

- Hourglass International

- Hourglass Royal Touch 300

- how to store cleanroom gloves and wipes

- Humidity

- Humidity Indicator Cards

- Ideal-Tek

- Indium

- Indium 8.9HF

- Indium 8.9HF lead-free solder paste

- Indium solder

- Industrial and Kitchen Safety Apparel

- Industrial Bench Magnifiers

- Industrial Gloves

- Industrial Storage

- industrial swabs

- Insulative

- Ionizer

- Ionizers

- Ionizing Gun

- IPA

- IPC Expo 2023

- ISO 4

- ISO 5

- ISO 6

- ISO 7

- ISO 8

- ISO Class 3–8 cleanroom supplies

- ISO cleanroom compliance checklist

- ISO Gowns

- Isolation Gowns

- Isopropyl Alcohol

- Jar Solder

- JBC Tools

- JEDEC J-STD packaging standards

- JNJ Industries

- Kapton Dots

- Kapton Tape

- Kapton Tape Discounted

- Keystone Arm Guards

- Keystone Beard Covers

- Keystone bouffant caps cleanroom

- Keystone Safety

- KFM

- Kitting and Assembly

- Kitting Trays

- Kolver

- Label Printers

- Labeling

- labels

- Latex

- Lead Free Solder

- Lead Paint Test Kit

- Lead Solder

- Lead Testing

- Lead-Free Wire Solder

- LFM

- Lindstrom

- lint free cleanroom swabs

- Lint-Free Cleanroom Supplies

- Loctite

- Louvered Wall Mount

- low lint cleanroom wipes

- Low VOC

- low-spatter

- Made in the USA

- Magnifying Lamp

- Magnifying Lamps

- Mailers

- Manufacturing Adhesives

- Material Handing

- Material Handling

- Material Storage

- Materials

- Matting

- Medical Grade Gloves

- Medical Storage

- medical swabs

- Metal-In

- Metal-Out

- MG Chemcials Swabs

- MG Chemicals

- MG Chemicals UVLED82

- micro-tip swabs cleanroom use

- Microscope Adapter Ring

- Microscopes for Forensics

- Mistakes in Repairing Circuit Boards

- Moisture Barrier Bags

- Moisture Control

- Moisure Barrier Bags

- Monitoring Humidity

- Mops

- Mr Ouch Labels

- MTE Solutions

- NASE-1C Nano Rework Station

- Needle Nose Pliers

- Nickel Conductive Coating

- Nitrile

- Nitrile Cleanroom Gloves

- Nitrile Exam Gloves

- No Clean Flux

- No Clean Solder Paste

- Nozzle Tips

- O'Cedar

- O'Cedar Brooms

- O'Cedar Brushes

- O'Cedar Mops

- OEM & Electronic Assembly Products

- oven

- Overhead ESD Workstation Solution

- Packaging

- packaging for ISO cleanroom compliance

- Paint Test Kit

- paste

- PCB Repair

- PCBS

- Permabond

- Permabond 825

- Permabond Adhesives

- Permabond ET5422

- Personal Grounding

- PFAS-free

- Physical Vapor Deposition

- Pliers

- Polyester Knit Wipes

- polyester swabs for cleanrooms

- Polyimide and Kapton Tapes

- Polymide Dots

- Polymide Tape

- Powder Free Nitrile Gloves

- PPE

- Precision Tools

- Precision Tweezers

- Preforms

- Presaturated IPA Wipes

- Presaturated Wipes

- Production Basics

- profile

- Protektive Pak

- Puritan

- Puritan Swabs

- Purus International Cleanroom Mats

- PVA Nozzle Extension Tip

- PVD

- Quantum Storage

- Reel Storage

- reflow

- Retaining Compounds

- Retractile Cord Manufacturing

- Retractile Cords

- Rework

- robotics

- Roll-O-Matic

- Rosin

- Round Nose Pliers

- RoyalTouch300 Nitrile Exam Gloves

- SAC305

- Safe Degreasers

- Safety Sleeves

- Scissors

- Screwdrivers

- SCS

- Shelf Life of Cleanroom Products

- Shelf Life of ESD Bags

- Shipping

- Sleeves

- SMS

- Sn63/Pb37

- SN995

- Soder-Wick

- solder

- Solder Evaluation

- Solder Flux

- Solder made in the USA

- Solder Paste

- solder paste cleanup wipes

- Solder Stations

- Solder Tips

- Solder Wick

- Solder Wire

- Soldering Materials

- Soldering Station

- Sole Grounders

- Spatulas

- SPC

- Specialty Tweezers

- Spill Control

- Spill Control Products

- Spill Kits

- Sponge Roller Mops

- Static Control

- Static Control Gloves

- Static Dissipative

- Static Shielding

- Static Shielding Bags

- Static Wipes

- Steel Pliers

- Steinel

- Steinel Professional Heat Guns

- Stencil Rolls

- Stencil WIpes

- Stencil Wiping Rolls

- stencil wiping rolls SMT

- Stereo Microscopes

- sterile cleanroom packaging

- Sticky Mats

- sticky mats for cleanrooms

- Stocked Items

- Storage

- Storage Bins

- Storage Systems

- Structural Adhesives

- Superwick

- Surface and Mat Cleaner

- Surface Resistivity Meters

- Sustainable Cleanroom Products

- swabs

- swabs for pharmaceuticals biotech aerospace

- Swabs Made in the USA

- Tack Flux

- Tacky Floor Mat Placement

- Tacky Mats

- Tacky Traxx

- Techspray

- Techspray Swabs

- Techspray Wipes

- Teknipure

- Teknipure Cleanroom Wipes

- Teknipure Swabs

- Teknipure Wipes

- TekniSwabs

- Temperature & Static

- Test for Lead Paint Kit

- Texwipe Alternative

- Thermal Interface

- Thermaltronics

- Threadlockers

- Titanium Blue Tweezers

- Titanium Tweezers

- Tools

- Top 10 Selling Products

- top cleanroom essentials

- Top Selling Products at MTE Solutions

- Totes

- Transforming Technologies

- Transforming Technologies ESD Mats

- Tronex

- Tweezers

- Understencil Wiping

- Unitron

- Universal Snap Kit

- UV LED Adhesive

- UVLED82

- Vileda Professional

- Virtu-Clean

- Virtu-Clean Class 100 Nitrile Gloves

- Vision Luxo

- Wall Storage

- Water Soluble Flux

- WAVE

- What are ESD Gloves

- What is ESD

- Winter

- Winter Protection

- Wipers

- Wipes

- Wiping Supplies for Cleanrooms

- Work Bench

- Work Station

- Workbenches

- Wrenches

- Wrist Straps